Car Parts Mold: Revolutionizing the Automotive Industry

Molding for automotive components has been revolutionized with the introduction of car parts mold technology. This innovative method has become increasingly popular in the manufacturing industry due to its efficiency, versatility, and cost-effectiveness. In t car parts mold his article, we will explore the various aspects of car parts mold, including its manufacturing process, features, advantages, usage methods, how to select the right product for your needs, and conclude with a summary.

Manufacturing Process:

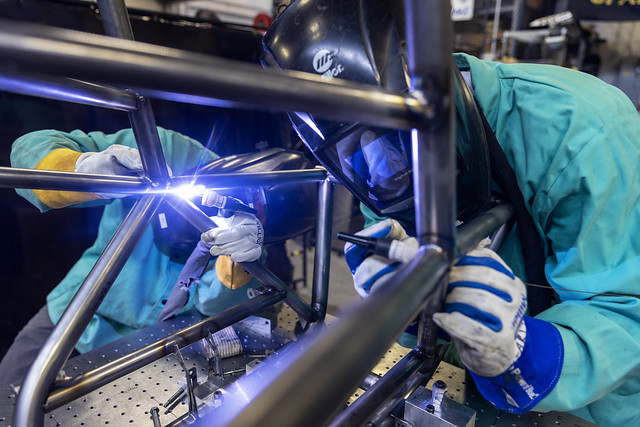

Car parts molds are produced through a precise and intricate process that involves designing and creating custom molds specifically for automobile components. These mol car parts mold ds are typically made from high-quality steel or aluminum alloy to ensure durability and accuracy during production. The initial step involves careful analysis of the component’s design specifications using computer-aided design (CAD) software. Once the design is finalized, it is translated into a mold structure using computer numerical control (CNC) machining techniques. The final step involve Molding for automotive components s injecting molten materials into these molds under controlled conditions to form the desired car part.

Features:

One of the key features of car parts molding is its ability to produce complex-shaped components accurately and efficiently. The use of advanced technologies allows manufacturers to create intricate designs without compromising on qual nozzle supplier ity or precision. Additionally, these molds can be customized based on specific requirements such as size variations or additional functionalities.

Advantages:

The utilization of car parts mold offers several advantages over traditional manufac car parts mold turing methods. Firstly, it enables mass production at a faster rate while maintaining consistent quality standards throughout each piece produced. This not only enhances productivity but also reduces overall production costs significantly.

Secondly,the enhanced precision offered by this technology ensures that every finished part meets strict tolerances and fits perfectly within vehicles’ Auto parts mold assembly processes.Thirdly,it permits flexibility in material selection.Based on individual needs,multiples types like metal alloys,fiber-reinforced plastics,rubber polymers,and more could be employed.Finally, the molds’ durability ensures a long lifespan, minimizing costs associated with frequent replacements.

Usage Methods:

Car parts mold plays a crucial role in the automotive industry. It is primarily used to manufacture various vehicle components such as interior and exterior trims, engine parts, electrical systems, and more.The versatility of this technology Mold for car parts enables manufacturers to create custom-made solutions for different vehicle models,satisfying diverse customer demands.

How To Select the Right Product:

To ensure the successful execution of car parts molding projects,you must consider certain factors when selecting a supplier.Firstly,the supplier’s experience,past records,and reputation should be carefully assessed.Secondly,certifications like

ISO standards indicate their commitment to quality control.Thirdly,the range of materials offered and available customization options are critical spray nozzle manufacturer considerations.Finally,cost competitiveness without compromising on quality should also be taken into account while making your decision.

Conclusion:

Car parts mold has drastically transformed the automotive industry,making it possible to produce high-quality components at an unprecedented rate.This technology offers numerous benefits such as precision manufacturing,durable products,freedom in design complexity,and cost-effectiveness.Its ability to cater to multiple material selections adds further versatility.Car parts mold is undeniably an essential tool for car parts mold any automobile manufacturer or supplier seeking competitive advantages in today’s market. Embracing this technology will undoubtedly pave the way for success and future growth.