Perfume Filling Machines: Revolutionizing the Fragrance Industry

Introduction:

In the dyn Odor sealing machines amic and fast-paced fragrance industry, manufacturers rely on advanced automation equipment to enhance their production processes. Perfume filling machines have emerged as a game-changer in this domain. This article delves into the manufacturing process, features, advantages, usage methods, tips for selecting these machines, and concludes with an overview of their significance.

Manufacturing Proc Essence filling devices ess:

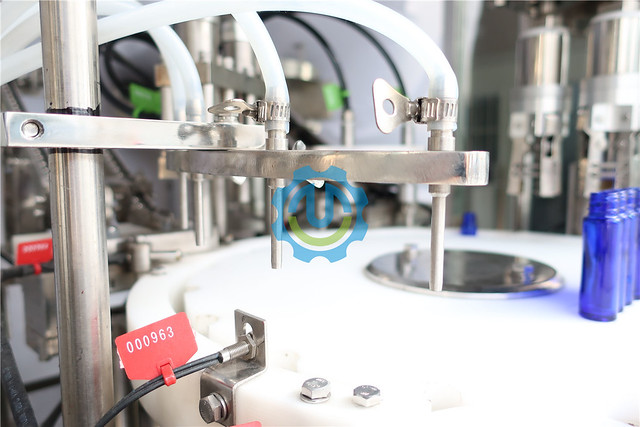

Perfume filling machines are engineered using cutting-edge technology and innovative design concepts. These devices consist of several components such as Essence filling devices, Aroma dispensing systems, and Odor s Automation equipment supplier ealing machines. Combined together in a cohesive manner, these elements ensure seamless perfume packaging.

Features:

The perfume filling machines boast a plethora of features that cater to the specific needs of fragrance manufacturers. First and foremost is their impeccable accuracy when it comes to mea perfume filling series suring precise quantities of liquid perfumes during the filling process. Additionally, these machinery units are equipped with high-speed mechanisms that enable efficient production rates without compromising quality standards.

Advantages:

The adoption of perfume filling machines offers numerous adv perfume filling machines antages over traditional manual labor-intensive methods:

1) Increased Efficiency: The automation provided by these machines significantly reduces human error while improving productivity levels.

2) Time-saving: Manual operations take considerably more time compared to automated systems which can fill multiple bottles simultaneously.

3) Cost-effective: By Filling capping labeling series reducing wastage through accurate measurements and minimized human intervention required for each step,

perfum Aroma dispensing systems e filling

Usage Methods:

Utilizing perfume filing machinery is relatively straightforward thanks to their user-friendly interfaces; however proper training is advisable beforehand to maximize operational efficiency.Depending on specific models,and complexity level,machines might need ongoing routine maintenance,hence regular monitoring cleaning ensures optimized performance.

How to Select Product:

When choosing a suitable perfume filing machine,you sho perfume filling machines uld consider:

1) Production Capacity: Assess your expected output requirements.

2) Compatibility: Ensure compatibility with various bottle sizes,fragrance densities,and closure mechanisms.

3) Reliable Supplier: Select a reputable automation equip perfume filling machines ment supplier with proven expertise and customer testimonials.

Conclusion:

In conclusion, perfume filling machines have revolutionized the fragrance industry by offering impeccable accuracy, efficiency, and cost-effectiveness. With their advanced features and user-friendly i

nterfaces, these devices streamline production processes while maintaining high-quality standards. If you are looking to enhance your fragrance manufacturing operations, investing in perfume filin

g machines is indeed a wise choice.

Remember,

perfume filling machines

perfume filling machines

Filling capping labeling series