Brass Locating Pins: Reliable Tools for Precision Alignment

Manufacturing Process:

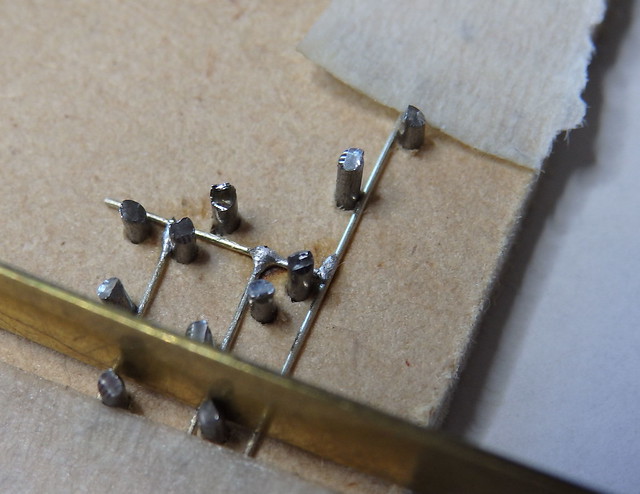

Brass locating pins are precision tools used in various industries for aligning an locator pin d positioning components accurately. These pins are typically manufactured using high-quality brass material. The manufacturing process involves cutting brass rods into desired lengths, followed by machining to achieve the required dimensions and tolerances. After the machining process, the pin

heads are formed using special tools or machines. Finally, the pins undergo a surface treatment such as polishing or plating to enhance their durability and resistance to wear.

Characteristics:

Brass locating pins possess several desirable characteristics that make them ideal for precision alignment tasks. Firstly, brass is known for i Brass locator pins ts excellent dimensional stability, ensuring consistent accuracy even under demanding conditions. Secondly, brass has good corrosion r

esistance properties, making these pins suitable for use in both indoor and outdoor environments. Additionally, they exhibit low friction with mating surfaces due to their smooth finish, preventing any potential damage during alignment operations.

Advantage brass locating pins s:

The use of brass locating spindles offers numerous advantages over other materials like steel or plastic alternatives. Firstly, brass has a higher heat conductivity compared to plastics while offering similar insulation properties as non-conductive materials like ceramics; this makes it superior when dealing with temperature-sensitive applications. Secondly, brass is less prone to scratching or m brass locating pins arring delicate parts compared with steel counterparts due to its softer nature.

Usage:

To utilize Brass locator pins effectively in precise alignments, careful attention must be given while selecting an appropriate diameter and length based on specific application requirements. These pins can be inserted into pre-drilled holes or bushings until fully seated against one component’s surface brass locating pins before engaging another component’s mounting hole onto it securely.

How to Choose Brass Locating Pins?

When choosing Brass locators’ pegs for your application consider key Brass locating spindles factors such as load capacity requirements (which determines the appropriate diameter), desired range of motion allowed between components (related mostly depending on length), and environmental conditions (for example, extreme temperatures or humidity). Additionally, consider compatibility with mating materials to avoid galvanic corrosion between dissimilar metals. Alway brass locating pins s consult the manufacturer’s guidelines for recommendations specific to your needs.

Conclusion:

Brass locating p Brass guide pins ins are indispensable tools in various industries where precision alignment is crucial for optimal performance. Their manufacturing process ensures high-quality dimensions and tolerances, while their characteristics of dimensional stability, corrosion resistance, and low friction contribute to their reliability. With careful selection based on application requirements and adherence to proper usage methods outlined by manufacturers, users can achieve accurate alignments efficiently using these reliable brass locator pins brass locating pins .