Manual Pallet Jack: A Versatile Lifting Equipment for Efficient Material Handling

Introduction:

In today’s fast-paced industrial setting, efficient material handling is essential for productivity and profitability. Manual pallet jacks have emerg Non-powered pallet lifter ed as indispensable tools in warehouses, distribution centers, and retail stores due to their ease of use and versatility.

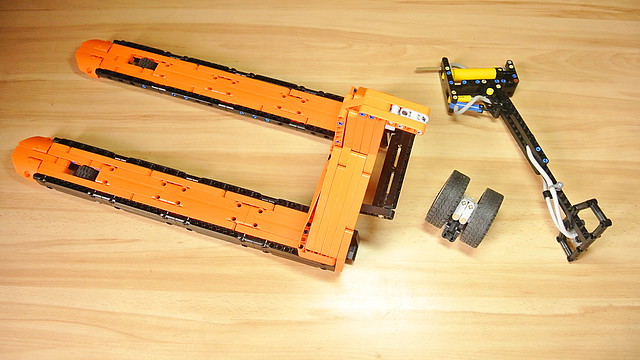

Manufacturing Process:

Manual pallet jacks are typically made using high-quality steel frames that ensure durability and longevity. The forks are designed to withstand heavy loads while mai manual pallet jack ntaining stability during transportation. The wheels, usually made of polyurethane or nylon, provide smooth maneuverability across various surfaces.

Key Features:

– Manual Pallet Trolley: This variant of the manual pallet jack offers a co manual pallet jack mpact design, making it suitable for narrow aisles and tight spaces.

– Non-powered Pallet Lifter: Being manually operated eliminates the need for power sources or batteries, reducing maintenance costs.

– Hand-controlled Pallet Mover: Ergonomically designed handles allow operators to easily control the movement of the load without exerting excessive force.

– Hand Pallet Truck: Equipped with a hydraulic pump mechanism that enables effortless lifting and lowering of loads within weight capacity.

Advantages:

1. Cost-effectiveness – Manual pallet jacks offer an affordable solution compared to thei lifting equipment manufacturer r powered counterparts, making them accessible to businesses of all sizes.

2. Versatility – These devices can be used in diverse industries such as logistics, manufacturing facilities, wholesale operations where goods need to be transported efficiently.

3. Increased Efficiency – With manual pallet jacks’ assistance, Hand-controlled pallet mover workers can move heavy loads quickly from one location to another without undue physical strain.

4. Easy Maintenance – Due to its simple mechanical construction powered by operator strength alone (no motors or electronic components), maintenance requirements are minimal compared with motorized options.

Usage Methodology:

Using a manual pallet jack involves several key steps:

1. Star manual pallet stacker t by ensuring that the device is in good working condition – check wheel alignment, handle grip, and load capacity.

2. Position the forks of the jack under the pallet or skid, ensuring they are centered for balanced lifting.

3. Pump the handle up and down to raise the forks off the ground until it reaches your desired height.

4. Carefully manual pallet jack steer or push/pull the loaded pallet jack to its destination.

5. Once at the destination, slowly lower the forks by releasing pressure on the hydraulic pump.

How to Select a Manual Pallet Jack:

To select an appropriate manual pallet jack for your specific needs, consider these factors:

1. Load Capacity – Calculate your maximum required weight capacity considering both static

(when stationary) and dynamic (during movement) loads.

2. Fork Length – Choose a fork length suitable for your typical load dimensions while ensuring adequate maneuverability in tight spaces if needed.

3. Wheel Type – Selecting wheel material is crucial depending on floor type (smooth or rough surfaces), noise concerns, and potential environmental constraints like manual pallet jack chemical exposure or temperature variations.

Conclusion:

The manual pallet jack has become an indispensable tool in modern material handling operations due to its simplicity, versatility, and cost-effectiveness advantages offers over powered alternatives. Whether you require a non-powered lifter such as a hand-controlled mover handheld trolley-like device or traditional hand-operated truck-style equipment; there’s always a variant ideally suite Manual pallet trolley d for your specific requirements within any industrial environment.

Investing in such durable yet affordable lifting equipment from reputable manufacturers ensures smoother workflow execution while increasing work efficiency across various industries globally.