Title: perfume filling series The Efficiency of Perfume Filling Machines

Perfume filling machines, also known as essence filling devices or incense bottling apparatuses, are essential components in the perfumery packaging machinery industry. These scent filling equipment play a crucial role in the manufacturing process of perfumes, ensuring efficiency and accuracy in every bottle that is produced.

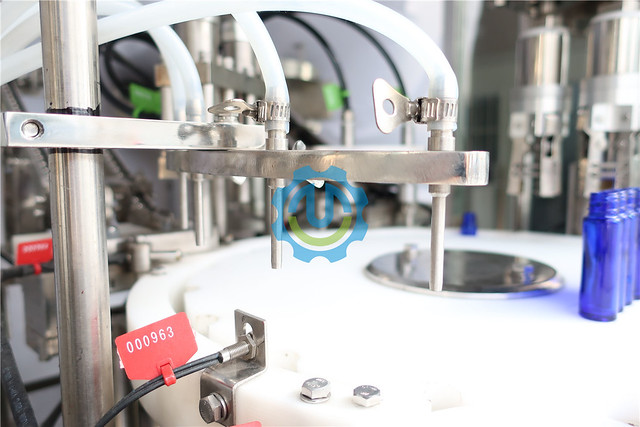

Manufactured through advanced technology, perfume filling machines are designed to st Incense bottling apparatuses reamline the production process. With their automated features, they can fill, cap, and label bottles wi perfume filling machines th precision and consistency. This automation equipment supplier offers a range of perfume filling series that cater to different production needs.

The key feature of these machines is their ability to handle various viscosities of liquids with perfume filling machines out compromising on quality. The high level of customization allows for quick changeovers between different scents and bottle sizes, making them versatile for any perfumery operation.

One advantage of using perfume filling machines is the reduction in labor costs and human errors. By automating the process, companies can increase their production o Automation equipment supplier utput while maintaining product quality standards. Additionally, these machines Essence filling devices are built to last with minimal maintenance required, ensuring long-term reliability.

To use a perfume filling machine effectively, one must first calibrate it according to the specific requirements of the fragrance being filled. Proper training should be provided to operators to ensure safe usage and optimal performance. Regular cleaning and maintenance routines should also be followed to prolong Perfumery packaging machinery the lifespan of the machine.

When selecting a perfume filling machine for you

r business, consider factors such as production volume, types of fragrances used, budget constraints,and future growth potential.Before making a decision,researching reputable suppliers and reading customer reviews can help you make an informed choice based on your specific needs.

In conclusion,the useof doesn’t perfume filling machines replace manual labor entirely,but enhances productivityand efficiencyinperfume manufacturing.Theinvestmentinaqualityperfumefillingmachinecanresultinlong-termcostsavingswhileensuringconsistentproductqualityandsatisfyingcustomerdemands.Choosingthesuitableequipmentsupplierwillbeanassuranceofreliableperformanceandon-goingtechnicalsupport.Itisage

quippedswith innovative features,makingita valuableassettoanyperfumerbusiness.Themaximumprofitabilityandreliabilitycanbeachievedbyincorporatinganautomatedapproachthroughtheproperutilizationofp Filling capping labeling series erfumefillingmachinesintotheoperationprocesses”.